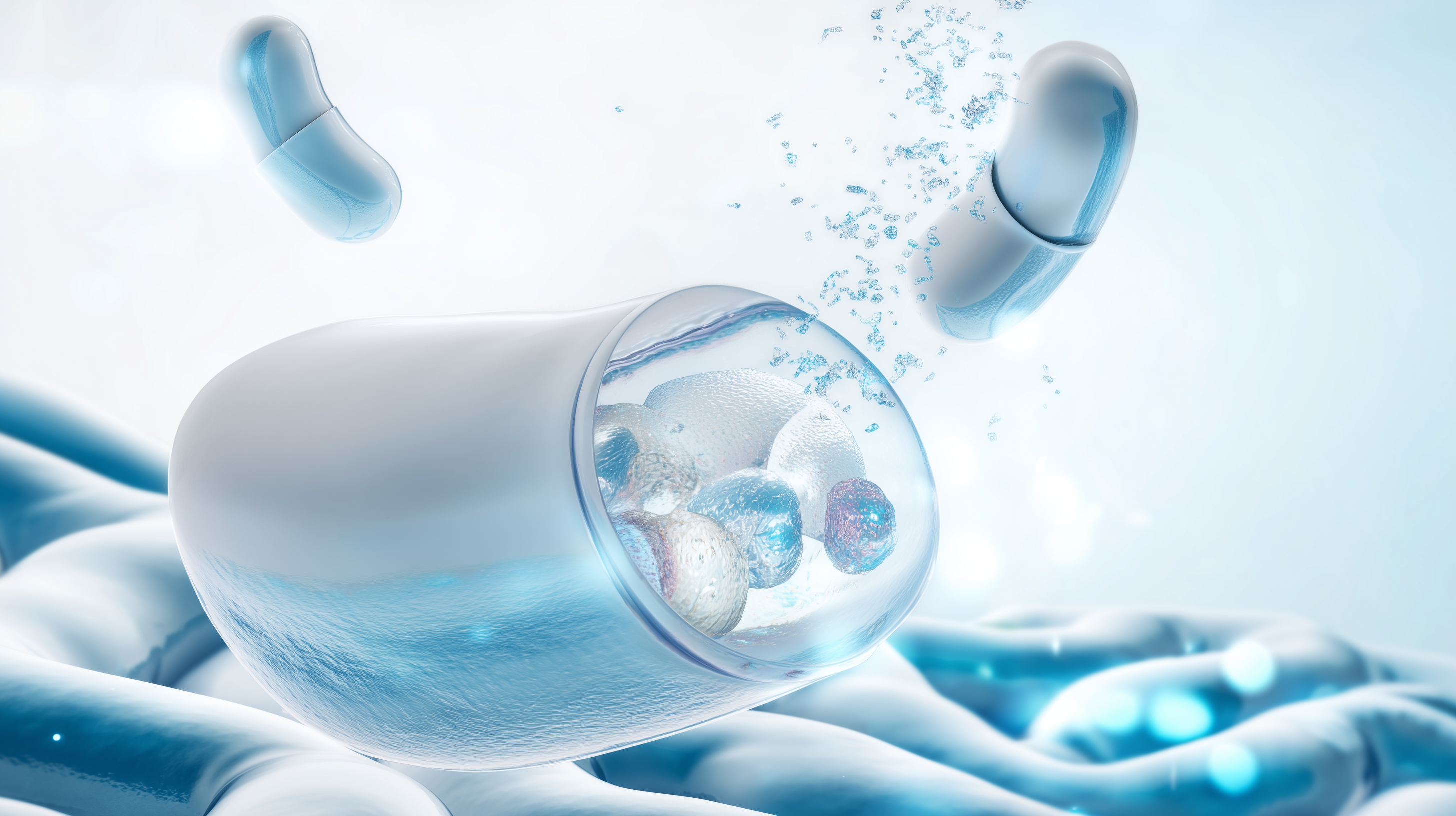

How our digestive system deals with capsules

The human digestive tract is a highly complex system that precisely coordinates chemical, enzymatic, and mechanical processes. Food and ingested substances pass through several stages with distinctly different conditions.

The stomach is a highly acidic environment, with a pH between 1 and 3. This environment is necessary for denaturing proteins and killing pathogens. However, many sensitive substances, including certain enzymes, vitamins, or plant extracts, can be rapidly inactivated or chemically altered in this environment.

In the small intestine , on the other hand, the pH is between 6 and 8 – significantly milder and slightly alkaline. This is where many micronutrients, minerals, and bioactive compounds are absorbed . Therefore, the site of release plays a crucial role:

If an active ingredient or nutrient is released too early, i.e., in the stomach, its stability or bioavailability may decrease. However, if the release occurs specifically in the small intestine, sensitive molecules can better preserve their structure and function.

Examples of gastric acid sensitive substances :

-

Enzymes (e.g. bromelain, papain)

-

Bases or bicarbonate-containing compounds

-

Probiotic microorganisms

-

Certain plant substances and polyphenols

For these groups of substances, enteric-coated capsules are technologically useful in order to bypass the stomach and only release their contents in the small intestine.

What does “enteric” mean?

The term enteric-coated refers to a formulation or capsule shell that is designed in such a way that it does not dissolve in the acidic environment of the stomach , but only in the neutral to alkaline environment of the intestine .

Functional principle

This effect is achieved through special materials or pH-sensitive polymers . The capsule shell remains intact in the stomach because it is insoluble in the stomach acid. Only when the pH rises—typically from around pH 5.5 to 6.8—does the shell dissolve, releasing the contents.

Materials and technologies

In pharmaceutical and nutritional practice, various substances are used for enteric coating, such as:

-

Hydroxypropylmethylcellulose (HPMC)

-

Cellulose acetate phthalate (CAP)

-

Plant polymers based on alginates or starch

These materials are chemically inert , meaning they do not react with the capsule contents and serve solely for protection and time-controlled release.

Advantage for sensitive substances

The enteric-coated technology protects sensitive ingredients from stomach acid and enzymes. At the same time, it enables targeted delivery to the site where absorption is physiologically most beneficial—the small intestine.

The DRcaps® technology in detail

One of the best-known modern variants is DRcaps® technology . Developed by Lonza (Capsugel) , it is one of the most widely used plant-based capsule solutions for dietary supplements.

What are DRcaps®?

DRcaps® are made from hydroxypropylmethylcellulose (HPMC) , a plant-based polymer that is completely vegan and free of synthetic coatings. These capsules require no additional coatings – the enteric-coating effect is achieved solely by the material structure of the capsule wall .

How it works

The DRcaps® shell swells slightly in acidic environments, yet remains closed and stable. It only dissolves after a certain period of time—in laboratory tests, approximately 45 to 60 minutes —and as the pH increases. The release is thus delayed and pH-dependent .

In vitro studies have shown that DRcaps® reliably retain the contents in gastric juice and only release them under conditions similar to those in the small intestine.

Benefits according to research

-

Protect sensitive ingredients from stomach acid

-

Delayed release for targeted absorption

-

Plant-based alternative to gelatin capsules

-

No additional chemical coatings necessary

From a scientific point of view, this is not an “active” effect, but a technological innovation that controls the location and time of release.

Scientific background – why release in the gut is crucial

The physiological relevance of release control arises from the structure of the digestive system. Most nutrients, vitamins, and bioactive molecules are absorbed through the mucosa of the small intestine.

Transport mechanisms in the intestine

Specialized transport proteins in the enterocytes (intestinal cells) act here to transfer substances into the bloodstream. Many substances must remain intact and chemically stable for this to happen – something that is often not guaranteed in the acidic environment of the stomach.

Sensitive substances

Enzymes, probiotic microorganisms, and certain polyphenols lose their structure upon contact with stomach acid. Delayed release can protect these substances and ensure that they only become active where their absorption or effect is intended.

Research and pharmaceutical technology

Enteric-coated systems have been established in pharmaceutical formulation research for decades. Studies in the European Journal of Pharmaceutics and Biopharmaceutics and Pharmaceutical Technology Europe show that pH-dependent release systems can significantly influence the stability and bioavailability of many substances.

The transfer of these findings to the field of nutritional supplements is increasingly taking place from the perspective of technology optimization – not therapeutic effect.

Gastric acid resistance vs. normal capsules – a comparison

| Characteristic | Regular gelatin capsule | Gastro-resistant capsule (e.g. DRcaps®) |

|---|---|---|

| material | Gelatin (animal) | Plant-based HPMC |

| resolution | Fast (in the stomach, < 10 minutes) | Delayed (45–60 minutes, pH dependent) |

| Protection of sensitive substances | Small amount | High |

| Release site | stomach | small intestine |

| Typical application | Insensitive materials | Acid-labile or pH-sensitive |

The choice of capsule technology therefore depends on the nature of the substance . An enteric-coated form is particularly useful if the ingredients:

-

could be inactivated by stomach acid,

-

require absorption in the small intestine, or

-

require delayed release.

However, for many vitamins and minerals, such technology is not absolutely necessary . What is crucial is the substance-specific tolerability and stability .

Quality and transparency in capsule technologies

As with all technological systems in the food or pharmaceutical industry, quality assurance plays a central role.

Purity and safety

Capsule materials are subject to the specifications of the European Pharmacopoeia and must meet defined criteria regarding purity, moisture content, stability and migration .

Labeling and standards

Manufacturers are required to disclose the composition of their capsules. Plant-based variants such as HPMC are often tested with ISO or GMP certificates . The EFSA and FDA have also classified HPMC as "Generally Recognized as Safe" (GRAS).

Traceability and laboratory analyses

Transparency is achieved when companies publish certificates of analysis (CoA) and laboratory reports . These documents prove that each batch has been tested for microbiological purity, heavy metals, and physical properties .

At BlueVitality, for example, the use of vegan DRcaps® stands for technological precision and tested purity – not as a promise of effectiveness, but as an expression of scientific diligence.

Conclusion – Technology in the service of compatibility

Enteric-coated capsules are a technologically sound method for protecting sensitive substances and releasing them specifically in the intestine .

Systems such as DRcaps® utilize plant-based polymers and pH-dependent mechanisms to enable delayed release – a concept that has long been established in pharmaceutical technology.

Not every substance requires this protection, but for pH-labile or enzyme-sensitive substances, it offers a clear functional advantage . It is crucial that such technologies are developed and tested in a scientifically transparent manner – in accordance with quality standards and physiological understanding.